A note about epoxy, it likes warm temperatures, 70 to 75 degrees is ideal. Geiger's boat shop is a basement that in the winter is between 50 and 60 degrees. I keep the epoxy containers in the bath room which is one of the warmest rooms in the house, this makes it easy to pump and mix the epoxy.

A note about epoxy, it likes warm temperatures, 70 to 75 degrees is ideal. Geiger's boat shop is a basement that in the winter is between 50 and 60 degrees. I keep the epoxy containers in the bath room which is one of the warmest rooms in the house, this makes it easy to pump and mix the epoxy.At right is the epoxy resin and hardener containers in the bathroom. I use and recommend Mas no blush, slow cure marine epoxy.

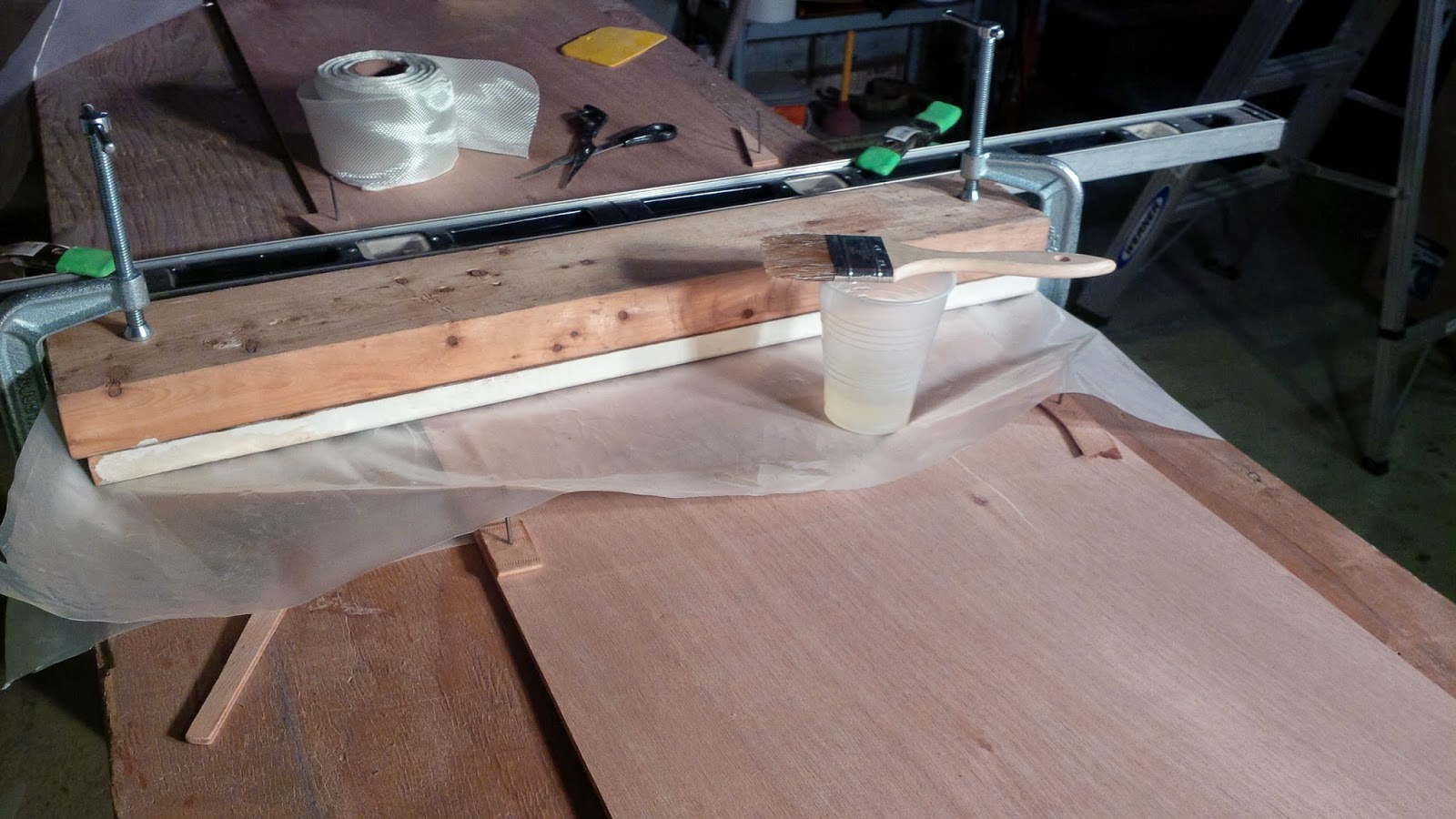

Below are all the tools and supplies I needed to create the butt joint.

I nailed the two blanks in place with finish nails and cut my fiber class tape to length. Notice the sheet of plastic under the butt joint. The plastic is needed to keep the joint from being glued to the table. A sharp pair of scissors is an important tool to have when working with fiberglass tape and fiberglass cloth.

Above is the mixed up epoxy and a 2 inch chip brush I used to apply the epoxy. The pumps on the epoxy containers are calibrated so that for every pump of resin you need a pump of hardener. For this batch I used five pumps of each which was way to much. When I do the butt joints for the other blanks I'll only use three pumps of each, hardener and resin and I hope to use it all and not have any left over.

In the picture above the fiberglass tape has been thoroughly saturated. You can tell it's saturated when it turns from white to clear. You only want to use just enough epoxy to turn the fiberglass clear. If you use too much the fiberglass will float and you will not get as strong a bond between the okoume and the fiberglass.

To finish up I put another sheet of clear plastic over the saturated fiberglass tape and then clamped the joint under a couple of boards so it will set up flat. Looking at the cup of epoxy it hardly looks like I used any. Time spent today was about 30 minutes.

No comments:

Post a Comment